Introduction

Aluminum traction boards have garnered significant attention among off-roading enthusiasts and adventurers. Known for their durability and resilience, these boards promise reliable vehicle recovery in challenging conditions. However, with their premium pricing and added weight, many wonder if aluminum traction boards are truly worth the investment. This article explores their durability, benefits, drawbacks, and how they compare to other materials.

Understanding the Purpose of Traction Boards

Traction boards serve a vital purpose for off-roaders, overlanders, and adventurers venturing into unpredictable terrain. When tires lose traction in mud, sand, or snow, traction boards provide a stable surface for the tires to grip, facilitating self-recovery without external assistance. They minimize the risk of getting stranded and reduce dependence on towing or winching.

The Rise of Aluminum Traction Boards in the Off-Roading Community

While plastic and composite traction boards have long dominated the market, aluminum variants are gaining popularity for their exceptional strength and longevity. Off-roaders seeking reliable recovery gear often turn to aluminum options, particularly for heavy-duty applications and frequent excursions into harsh environments.

Why Durability Matters in Recovery Gear

In remote locations, compromised recovery gear can lead to serious consequences. Traction boards face immense pressure from vehicle weight, jagged rocks, and abrasive terrain. Durability ensures boards retain their structural integrity under stress, providing reliable performance when it matters most.

What Are Aluminum Traction Boards?

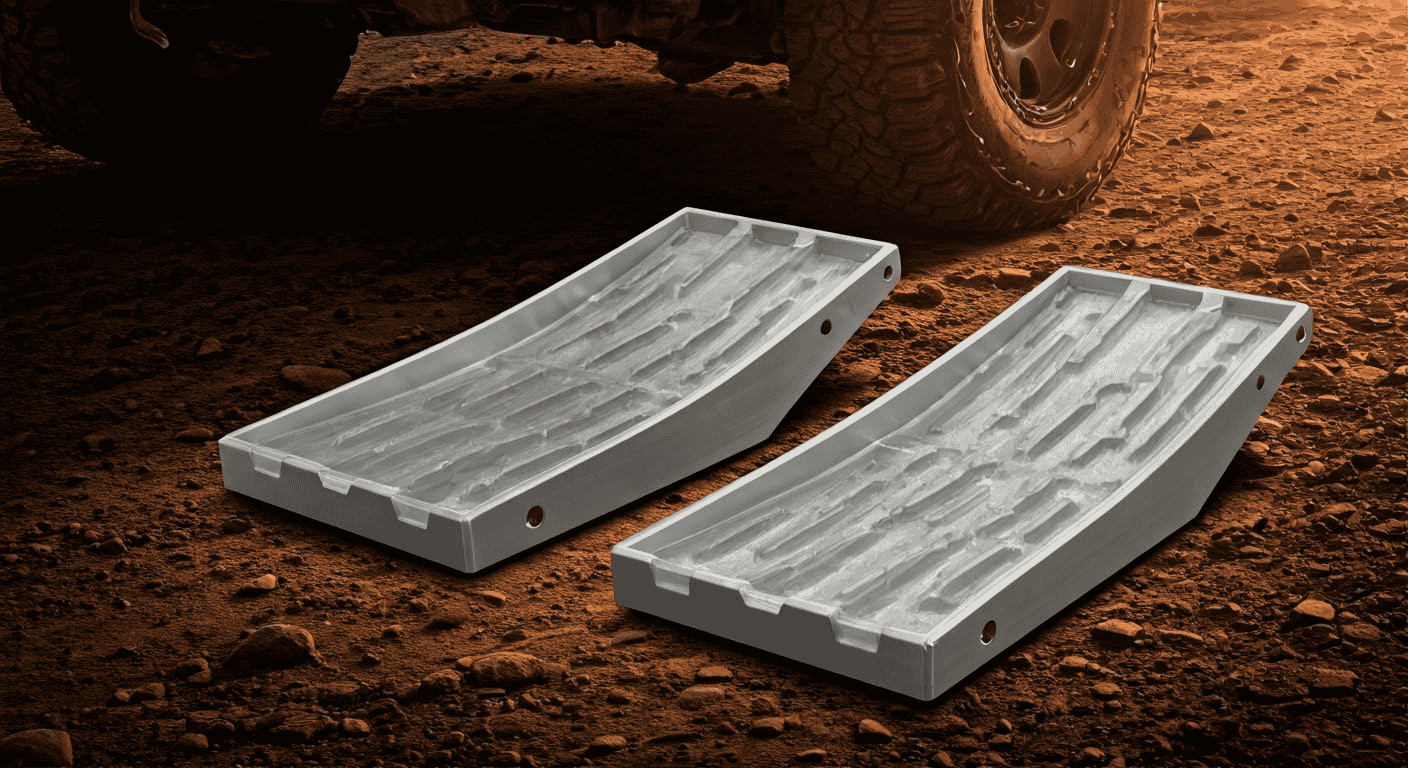

- Defining Aluminum Traction Boards and Their Key Features: Aluminum traction boards are robust recovery devices crafted from high-strength, corrosion-resistant aluminum alloys. Their key features often include aggressive tread patterns for superior tire grip, reinforced structural ribs for added resilience, and anodized or powder-coated finishes for enhanced longevity.

- How They Differ from Plastic and Composite Boards: Unlike plastic boards, aluminum options are impervious to UV degradation and extreme temperature changes. While plastic boards are lighter and more affordable, they are prone to cracking and warping. Composite boards offer a compromise, but aluminum remains unmatched in sheer strength.

- The Engineering Behind Aluminum Construction: Manufacturers often design aluminum boards using advanced engineering techniques, including precision welding and CNC machining. These methods ensure optimal load distribution and resistance to bending under pressure. Some models feature integrated handles, mounting points, and sand channels for multifunctional use.

Durability Under Pressure: Putting Aluminum Boards to the Test

- Real-World Scenarios Where Aluminum Shines: From remote desert trails to alpine snowfields, aluminum traction boards have proven their mettle. They excel in conditions where heavy vehicles and aggressive driving styles would compromise plastic alternatives. Recovery from sharp-edged rocks and heavily rutted trails further highlights their resilience.

- How Aluminum Withstands Extreme Conditions: Aluminum’s natural resistance to corrosion makes it ideal for wet, snowy, or salty environments. Unlike plastic, which can become brittle in cold weather, aluminum maintains its structural integrity across a wide temperature range.

- Performance in Different Terrains: Sand, Mud, Snow, and Rock: In soft sand, aluminum traction boards provide a broad surface area to distribute vehicle weight effectively. In mud, their rigid design prevents sagging, maintaining traction. On snow, their durability ensures effective self-recovery without fracturing under pressure. Rocks present a formidable challenge, but aluminum boards’ abrasion resistance makes them well-suited for the task.

Advantages of Aluminum Traction Boards

- Superior Strength and Load Capacity: Aluminum traction boards are capable of supporting the weight of large trucks, SUVs, and even fully-loaded overland vehicles. They endure tremendous stress without deformation, making them an ideal choice for heavy-duty applications.

- Resistance to Cracking, Bending, and Warping: Where plastic boards may crack upon impact, aluminum boards maintain their form. Their structural integrity ensures consistent performance, even after repeated recoveries.

- Long-Term Investment: Built to Last: Though aluminum boards may have a higher initial cost, their longevity makes them a worthwhile investment. With proper care, they can last for years without significant wear.

Potential Drawbacks of Aluminum Traction Boards

- Heft and Bulk: A Trade-Off for Strength: Aluminum boards are noticeably heavier than their plastic counterparts. While this added weight contributes to their durability, it can make handling and storage more challenging.

- Cost Considerations: Are They Worth the Price?: Premium materials and advanced manufacturing processes result in a higher price point. However, for frequent off-roaders or those operating in extreme environments, the investment may justify itself through longevity and reliability.

- Maintenance and Corrosion Resistance: Although aluminum resists corrosion, exposure to road salt and moisture can lead to oxidation. Proper maintenance, including cleaning and protective coatings, can mitigate this risk.

Comparing Aluminum to Other Materials

- Aluminum vs. Plastic: Which One Survives Tougher Terrain?: While plastic boards are lightweight and affordable, they lack the resilience of aluminum. Plastic boards may perform well in occasional use or softer terrain, but for rocky or demanding conditions, aluminum remains the superior choice.

- Composite Traction Boards: A Middle Ground?: Composite boards offer a balance between strength and weight. Often reinforced with fiberglass or resin, they are more durable than plastic yet lighter than aluminum. However, they still fall short of the sheer robustness of aluminum.

- Insights from Off-Road Enthusiasts and Recovery Experts: Seasoned off-roaders frequently advocate for aluminum boards when tackling rugged landscapes. Testimonials often highlight the boards’ reliability in real-world scenarios, reinforcing their reputation for durability.

When Are Aluminum Traction Boards the Best Choice?

- Ideal Scenarios for Aluminum Boards Over Alternatives: Aluminum boards are the preferred choice for heavy-duty vehicles, long-term overlanding expeditions, and unpredictable terrain. Their resilience in extreme environments makes them a go-to for professionals and serious adventurers.

- Vehicle Type and Load Weight Considerations: Larger, heavier vehicles exert greater pressure on recovery gear. Aluminum traction boards are better equipped to handle the weight of fully-loaded trucks, campers, or commercial vehicles.

- Recommendations for Frequent Overlanders and Heavy-Duty Applications: For those who prioritize preparedness and reliability, aluminum traction boards offer peace of mind. Whether navigating remote backcountry trails or working in rugged job sites, their durability ensures dependable recovery.

Maintenance Tips for Extending the Life of Aluminum Boards

- Proper Cleaning to Prevent Corrosion and Rust: Rinse off mud, salt, and debris after each use. Mild soap and water, followed by thorough drying, help prevent oxidation.

- Storage Solutions to Maintain Structural Integrity: Store boards in a dry, covered area to reduce exposure to moisture and UV radiation. Mounting them on external racks or vehicle sides is a convenient option for frequent use.

- Periodic Inspections and Repairs for Longevity: Regularly inspect boards for signs of wear, corrosion, or damage. Address minor scratches with touch-up paint or protective coatings to maintain longevity.

Conclusion

Are Aluminum Traction Boards Truly Durable or Just Hype?

Aluminum traction boards live up to their reputation as highly durable and reliable recovery tools. While they come at a premium cost, their exceptional strength and longevity often justify the investment.

Factors to Consider Before Making a Purchase

Evaluate your typical terrain, vehicle weight, and recovery needs. If durability and resilience are top priorities, aluminum boards are an excellent choice.

Final Thoughts for Off-Road Enthusiasts

For adventurers who push their vehicles to the limit, aluminum traction boards provide peace of mind and enhanced recovery capability. When the path ahead is unpredictable, these boards are a valuable companion on any journey.